About us

Years of experience

14

tons of aluminium delivered

54000

regular clients

350

countries we ship to

9

We build our growth on a combination of high-level skills, core competencies, professionalism, individual approach and personal commitment.

In the world of aluminium we focus on high-quality standards and technical perfection. Together with our clients we create long-term sustainable and unique value.

Material - aluminium, is the only thing we work with. This metal is a right choice to build a sustainable future. Its low weight, high durability and minimal maintenance allow us to develop more environmentally sustainable products.

Primary production of aluminium from the basic raw material aluminium oxide (Al2O3) needs a large amount of energy. But aluminium is a 100 % recyclable metal. It can be continously recycled and therefore it plays an important material choice in product‘s life cycle.

Its secondary production from aluminium scrap requires 5 % of the energy only compared to primary production. This choice reduces its environmental impact and low carbon footprint.

Production process

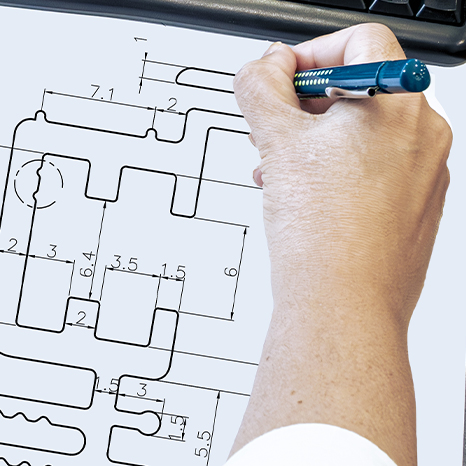

Design

During the design, we focus on gathering the necessary technical information, setting clear goals and securing the necessary production resources.

Documentation

Documentation plays a vital role in our service delivery process. It includes technical proposal and quotation, which are important for transparent information sharing.

Prototype

The prototype’s production starts on documentation’s approval by the client. It is a key step in the process of introducing a new aluminium profile into serial production.

Production

Serial production is focused to hit the ceiling of productivity. With careful planning and process optimization, we strive to minimize unnecessary delays and costs.

Delivery

Our priority is the fast delivery of aluminium materials. In this way, we ensure a smooth course of subsequent production processes for our clients.

Prototype delivery in 4-6 calendar weeks.

Serial production in 3-4 calendar weeks.

Some projects may require more time to find a compromise between client expectations and efficient production.

To speed up the production process, it is important to know:

- Requirements for the final quality of the aluminium profile.

- Requirements for manufacturing tolerances.

- Area of application of the manufactured aluminium profile.

- Production volumes.

- Surface treatment and finishing specifications.

.svg)